|

CT metal artifact reduction

|

|

Try the Metal Deletion Technique (MDT) Due to overwhelming demand, the free web interface for metal artifact reduction has been disabled. You can get a free copy of the MDT software (for internal non-commercial use). The software can be integrated with PACS: studies are sent to your server from PACS or from the scanner, and the processed images are automatically sent back to PACS as a new series under the same accession number. First, review the software manual. Next, complete and sign the licensing agreement and return it by email to revisionrads@gmail.com. Commercial licensing terms are available upon request.

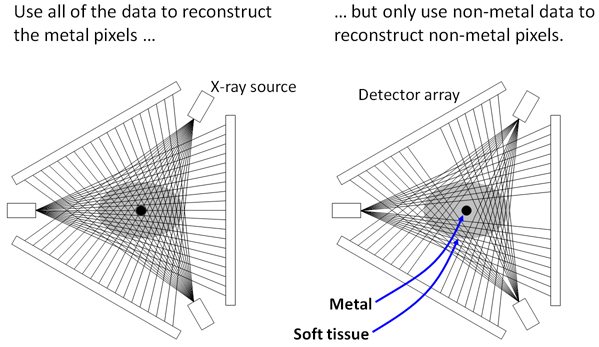

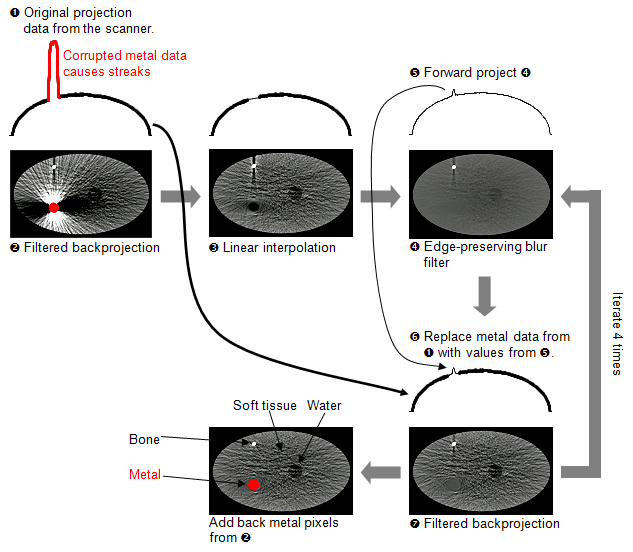

We start by forward projecting the reconstructed image, to get an estimate of the raw data from the scanner. Next, we use all of the projection data to reconstruct metal pixels, but only use the high quality non-metal data to reconstruct bone and soft tissue. This means that, instead of trying to look through the metal to see soft tissue, we look around the metal. We forward project the reconstructed image (with the metal pixels deleted), and use this to replace the inaccurate metal data. We perform this iteratively to improve the results.

In the diagram below, metal pixels and projection data are shown in red. The original projection data are plotted with a thick line, and revised projection data are plotted with a thin line.

Clinical evaluation In a blinded comparison against 3 other methods, two radiologists judged MDT to have the best image quality in 11 out of 11 scans (with a total of 178 slices containing metal) [1]. This is the first metal artifact reduction technique shown to have statistically significantly better image quality than another technique for clinical scans. In 2 of 11 scans, the improved image quality actually changed the diagnosis. This includes a case of rectal cancer that was missed with the current technology. These are the first reported cases of a metal artifact reduction algorithm changing the diagnosis. This study used raw projection data from the CT scanner. A follow up study of 80 patients showed that MDT improved image quality 73% of the time for small metal implants, and 75% of the time for large metal implants [3]. MDT had better image quality than 3 other metal artifact reduction techniques. This study used projection data that was simulated from images reconstructed by the scanner. More recent data shows that in 14% of scans, MDT changed the diagnosis, improved visualization of key findings, or improved diagnostic confidence (presented at RSNA 2012). An analysis by an independent research group showed that MDT outperformed commercial metal artifact reduction techniques from GE and Siemens [4].

1. Boas FE and Fleischmann D. (2011) "Evaluation of two iterative techniques for reducing metal artifacts in computed tomography." Radiology. 259(3): 894-902. 2. Boas FE and Fleischmann D. (2012) "Computed tomography artifacts: Causes and reduction techniques." Imaging in Medicine. 4(2): 229-40. 3. Golden C, Mazin SR, Boas FE, Tye G, Ghanouni P, Gold G, Sofilos M, Pelc NJ. (2011) "A comparison of four algorithms for metal artifact reduction in CT imaging." Proc. SPIE. 7961: 79612Y. 4. Wagenaar D, van der Graaf ER, van der Schaaf A, Greuter MJW. (2015) "Quantitative comparison of commercial and non-commercial metal artifact reduction techniques in computed tomography." PLOS One. 10(6): e0127932.

Abstract and slides from RSNA (11/26/2012). Video and slides from Stanford radiology grand rounds (4/3/2012). Slides from the International Society for Computed Tomography meeting (8/11/2011).

MDT is not FDA approved, and is only intended for research use. It is covered by US patent 8233586. Email us |